Contamination in the production environment during the adhesive process.

Introduction.

AKAB is a wonderful family business specializing in the production of custom-made interior doors. During our first meeting with Michel, we immediately felt a connection. Michel is a man with a unique vision and generously shares life lessons – all for free.

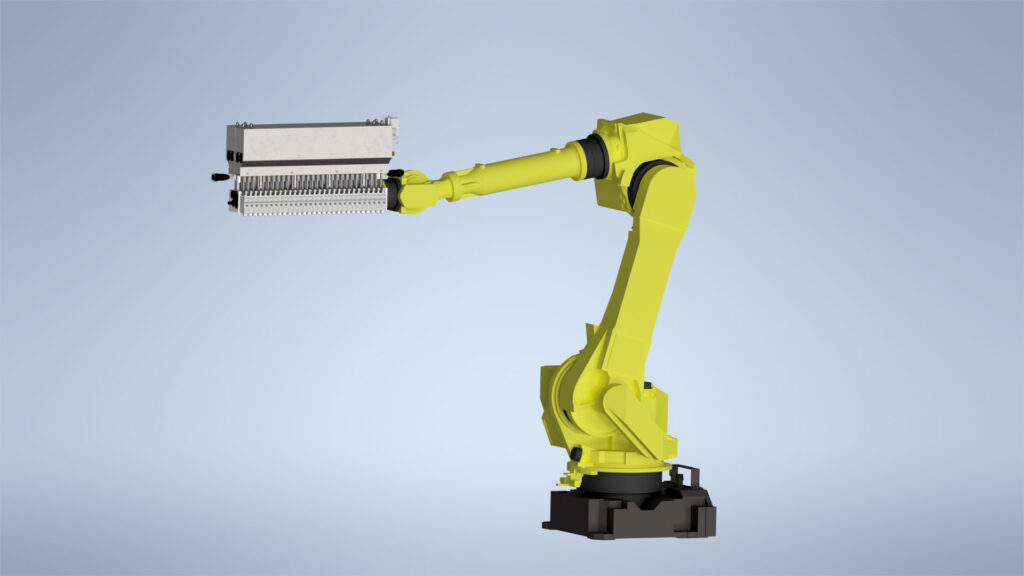

AKAB’s goal is to run production as if the lights are off. Thanks to a high level of robotization and automation, they can manufacture doors quickly and extremely efficiently, without compromising on quality.

The question of AKAB.

AKAB knocked on our door. During the application of PU Hotmelt glue, a lot of contamination occurred in the production environment. Each day, they spent up to 2 hours cleaning the equipment and workspace. Yes, you read that right – a full 2 hours!

On top of that, they experienced malfunctions, and the glue coverage was inconsistent. Something had to change, so together we worked on finding the right solution.

Case-Specific Challenges.

Contamination of the production environment

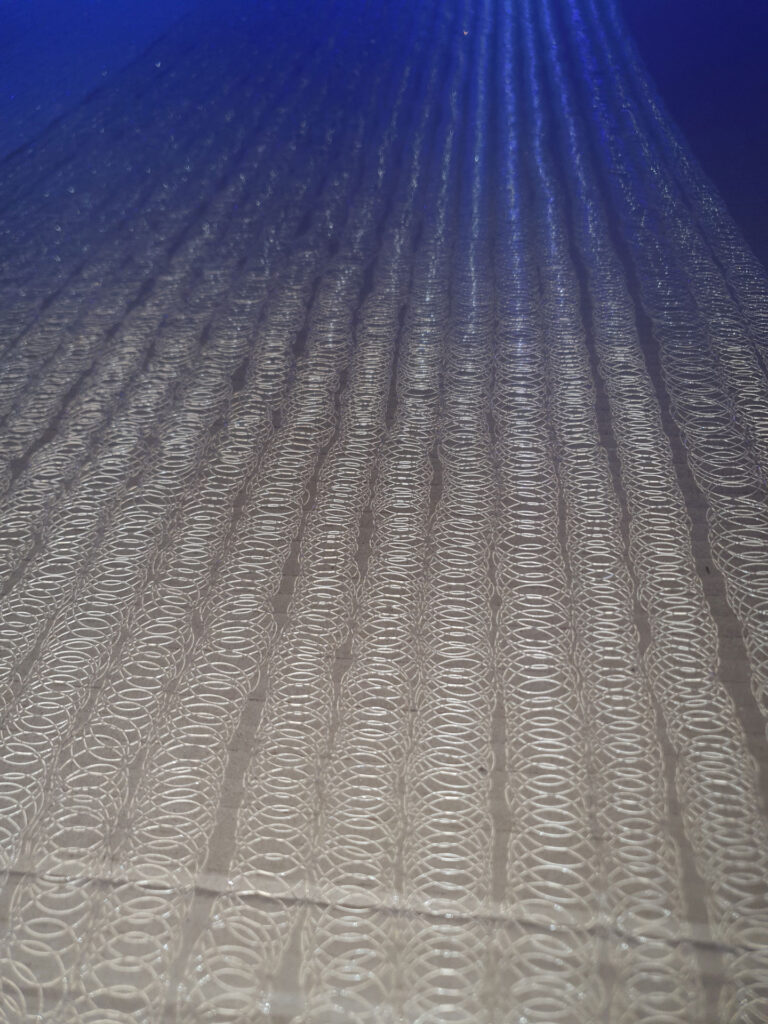

The adhesive head is not properly adjusted, causing overspray and leaving significant contamination after use. This excess adhesive accumulates on the equipment, requiring additional cleaning.

Adhesive loss and waste

The adhesive head cannot adjust to the size of the door, resulting in significant adhesive waste during production. This is not only costly but also leads to a less sustainable manufacturing process.

Malfunctions and downtime during production

Without a continuous flow in the adhesive process, especially during drum changes, production can be delayed, reducing overall productivity.

Solutions BIT Hotmelt Technology.

AKAB enlisted BIT Hotmelt Technology to jointly improve the adhesive process and reduce adhesive waste. The solutions provided by BIT Hotmelt Technology include:

- New adhesive head for reduced contamination & more efficient adhesive application

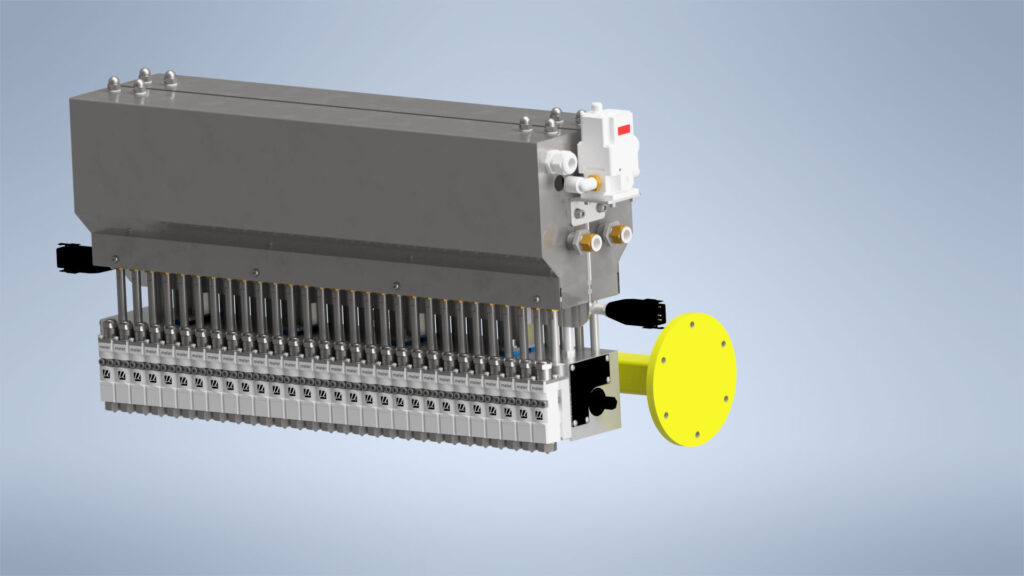

The advanced adhesive head eliminates contamination in the production environment and ensures precise, even adhesive application on the doors. It automatically adjusts to different door sizes, preventing adhesive waste and optimizing efficiency. - Upgraded Hotmelt unit – Macro 50-4 PUR

By installing a new Hotmelt unit between the existing drum melter and the new adhesive head, the adhesive process can continue uninterrupted during drum changes. The tank of the Hotmelt unit maintains a sufficient supply of molten adhesive, allowing drum changes to take place without production downtime. Additionally, the high-capacity pump ensures a consistent adhesive flow, guaranteeing a stable adhesive application from start to finish. - Swirl modules for a maintenance-free process

By integrating swirl modules with needle shut-off technology and precisely programmed adhesive and air control, the adhesive process becomes fully maintenance-free, ensuring continuous availability of the equipment.

Our achievements.

- Contamination in the production environment reduced to zero.

- Savings of 2 hours of cleaning per day.

- No adhesive waste due to the new adhesive head.

- Continuous adhesive process enabled by the new Hotmelt unit.

- Fully maintenance-free adhesive process.

”Thanks to BIT Hotmelt Technology, we can operate smoothly without issues. We highly recommend BIT Hotmelt Technology to solve problems in your production process!

MichelOwner - CEO

Questions or need more information?

Contact us, and we’ll be happy to assist you!